Manufacturing Process

-

Step 1

At the first unit, the steel is processed into 6 ft long pipes.

-

Step 2

Pipes are cut into pre-defined sizes which are then buffed and sent for chromium plating.

-

Step 3

The same process is applied with the handle, nutt and button of the lighter.

-

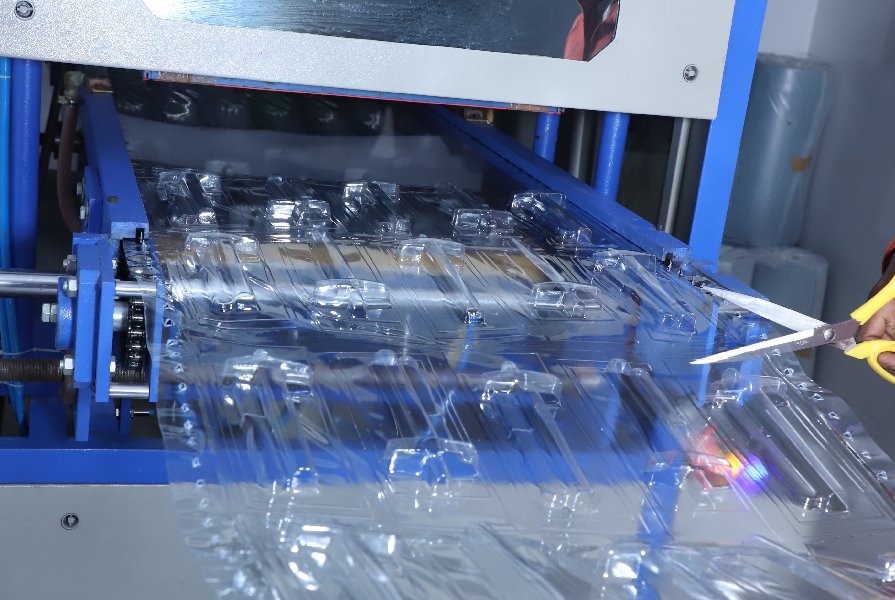

Step 4

At the second unit, the inner parts of the lighter are moulded from high quality PVC resin.

-

Step 5

Gift items such as stainless steel knife and peelers are also moulded at the same unit.

-

Step 6

Finished items which pass the quality check are brought to the third unit where they are assembled into a lighter.

-

Step 7

The lighter then passes through a quality check and is sent to the packing and forwarding unit.

-

Step 8

The packed lighter after passing several quality checks is then shipped to distributors spread across the country.